All persons that work in the Dangerous Goods/Hazardous Materials transportation field must be trained. Training requirements are based on the mode of transport (air, ocean, highway, rail) used and the job function performed. Do I need training?

| Mode | 49 CFR (USA Domestic) | ICAO/IATA (International Air) | IMDG (International Ocean) |

|---|---|---|---|

| Air | X | X | . |

| Ocean | X | . | X |

| Highway | X | . | . |

| Rail | X | . | . |

No matter which mode of transport used, the employer/employee must adhere to the training requirements under 49 CFR, Subpart H. For all modes, all job functions, the following apply:

- It is the employer's responsibility to ensure their employees receive training.

- The employee may not perform their duties unless they have received training.

- The employer may provide training or use an outside source.

- The training must include a test.

Employees Must Be Trained in the Following Areas:

- General Awareness training: provides familiarity with the requirements and allows employees to recognize hazardous materials (dangerous goods) in their workplace.

- Function-specific training: detailed job-specific training. Example; if you mark and label packages, your training must include detailed information on those subjects.

- Safety training: includes emergency response and measures to be taken in case of an emergency at your workplace. This training should also include proper handling procedures to avoid mishaps.

Other Requirements:

- The employee must be trained within 90 days of hire or a change in job function(s).

- Until trained, the employee may perform their job only under the direct supervision of a properly trained and knowledgeable hazmat employee.

- Relevant training received from a previous employer or other source will satisfy the requirements as long as you have training records from the previous employer.

- Employee records must be kept and include the following:

- Employee's name.

- Date of most recent completed training.

- A description, copy, or the location of the training materials used.

- Name and address of who provided the training.

- Certification that the employee has been trained and tested.

- For Canadian students - The Canadian Regulations called, Transport Dangerous Goods or TDG, Part 6.3 explains that the certificates must the items below; So for our Canadian friends, please make sure the name and address of your company is printed on your certificate regardless of who provides it.

- the name and address of the place of business of the employer; The place of business could be a local office, a regional office or a head office.

- the employee's name;

- the date the training certificate expires, preceded by the words “Expires on” or “Date d'expiration”; and

- the aspects of handling, offering for transport or transporting dangerous goods for which the employee is trained, including the specific topics set out in section 6.2.

- Other countries -Wherever you are in the world, please make sure your training needs and requirements meet the standards of your government.

Retention of Records:

Records of current training, as well as the preceding three years, must be maintained for each employee. If the employee leaves, the records must be kept for an additional 90 days. The training records must be made available upon request of the appropriate authority.

In addition to the above requirements under 49 CFR, if you transport by air or ocean, there are additional regulations you must comply with. For air transport on an IATA carrier, you must be certified to use the ICAO/IATA Dangerous Goods Regulations. For ocean shipments you must be trained according to the IMDG regulations. The training requirements are almost identical with the exception of recurrent training frequency.

Training Curriculum

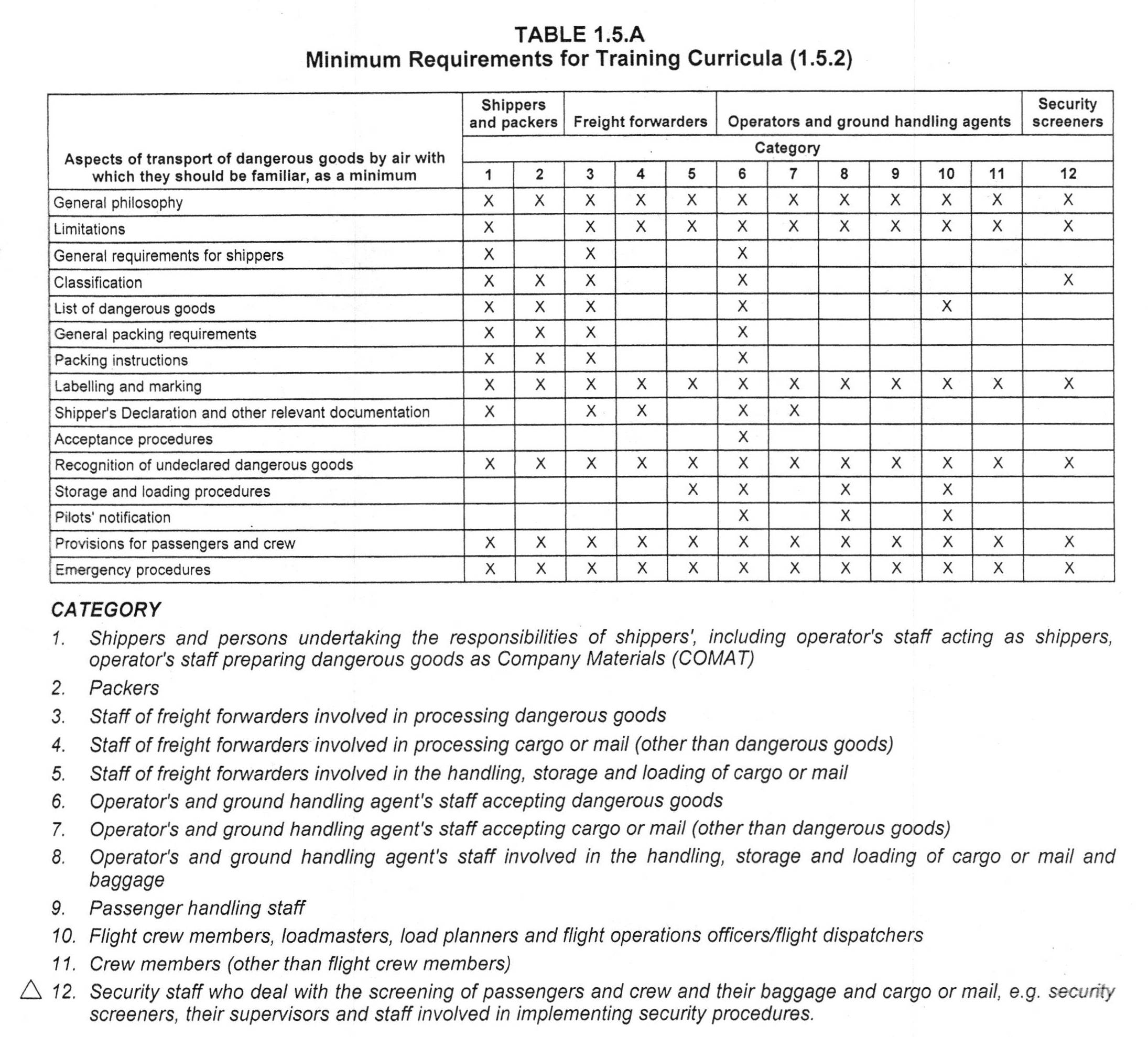

Table 1.5.A in the IATA Dangerous Goods Regulations is based on ICAO Table 6-1, Content of Training Courses. It may be used as a guideline applicable to most modes.

TABLE 1.5.A

Minimum Requirements for Training Curricula (1.5.2)

Once initial training has been completed, you must receive recurrent training to remain up-to-date on any changes to the regulations. The frequency depends on the mode or job. However, in addition to the chart indicating training frequencies, current US Department of Transportation regulations also state that "...training is required every time changes in the regulations occur." This pertains only to the hazardous materials you transport or your job function. *The IMDG Code does not reference a time frame therefore the 3-year recurrent period stated in 49 CFR, Subpart H, applies.

Recurrent Training Schedule

| Mode | 12 Months | 24 Months | 3 Years |

|---|---|---|---|

| Air | . | X | . |

| Airline Employees (within the USA only) | X | . | . |

| Highway | . | . | X |

| Rail | . | . | X |

| *Ocean | . | . | X |

The training requirement 49CFR 172.704 and IATA, Section 1.5 say training must include 1) General Awareness 2) Function Specific Training 3) Safety Training and 4) Security Awareness Training.

Any person who attends DGI 49CFR, IATA and/or IMDG training will have received the knowledge to properly identify the Proper Shipping Name and UN Number for lithium batteries and follow the procedures taught in our training to successfully prepare and ship lithium batteries. DGI training includes General Awareness and Function Specific.

It is ultimately the employers responsibility to ensure the employee knows and understands the batteries they are shipping. DGI training provides the tools for the employee to complete that task.

IATA and 49CFR have added language that states personnel shipping lithium batteries must receive “adequate” training. IATA provides a definition of “adequate” training in Section 1.6. that states:

The following is offered as a starting point for an employer on what could be considered as being adequate instruction:

1. The employer must identify the different configurations of lithium batteries that they ship, i.e. lithium batteries and/or lithium batteries packed with equipment and/or lithium batteries contained in equipment; lithium metal batteries and/or lithium ion batteries.

2. The employer must document the procedures that apply to the configurations and battery types that they ship as determined in 1, above.

3. The procedures should be written up as a clear work instruction or other information that is available to all employees responsible for the preparation of lithium battery shipments.

4. All employees that are involved in the process of preparing lithium battery shipments must be taken through the procedure to ensure that they understand and can demonstrate the correct application of documented procedures for the packing, labelling, marking and documentations requirements, as applicable to their job function.

5. A record must be maintained that identifies each applicable employee and the date(s) that this instruction was provided.

6. Employees should be given periodic refresher, or at least demonstrate that they remain “adequately” instructed on how to perform the task. This should be done at least every two years or whenever the procedure is revised, or regulations are changed, whichever is sooner.

7. Companies that are involved in reverse logistics, i.e. arranging for returns of lithium batteries, lithium batteries packed with equipment or lithium batteries contained in equipment must develop a clear instruction for consumers on the process to be followed for returning products. This instruction must include packaging materials and lithium battery marks, as necessary. The instruction must also include the transport method and mode of transport that must be followed; this must include a clear statement on applicable prohibitions.

IATA - International Air Transport Association Regulations,

ICAO - International Civil Aviation Organization

49 CFR - The 49th Code of Federal Regulations -

IMDG - International Maritime Dangerous Goods Code.

14 CFR - Code of Federal Regulations, Subpart A, Part 121.433a and 135.333.